Description

The photos in this edition are black and white.

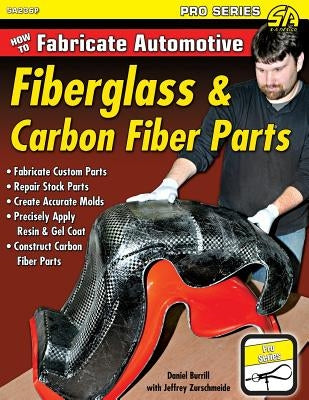

Fiberglass and composite parts are commonly used in many collector cars, hot rods, Corvettes, and even late-model vehicles. Body panels, interior components, and engine parts are fabricated from fiberglass and composite materials (plastic molded or carbon fiber). While other fiberglass and composite material books have been published, few are focused on fabricating and repairing automotive parts, and this book concentrates on completing common and advanced projects at home in the garage.

The reader is shown how to use glass strand mat, woven fiberglass cloth, carbon fiber cloth, and hybrid fabrics for particular applications. The strength of these mats and ideal uses are covered in detail. Also shown is how to correctly mix the typical resins (polyester, epoxy), hardeners, and gels. Core materials, such as wood, foam, and honeycomb Nomex, are often used to add strength to various parts. All the relevant tools, including mixing containers, holding containers, saws, scissors, files, and shaping tools, are discussed. Constructing patterns to exacting standards from wood, Formica, aluminum, and other materials is essential and covered in detail.

Whether repairing existing components, fabricating new ones, building a race car, or restoring a classic, this is the one book to guide the reader through each critical stage.

Author: Dan Burrill, Jeffrey Zurschmeide

Publisher: Cartech

Published: 08/28/2012

Pages: 162

Binding Type: Paperback

Weight: 0.86lbs

Size: 11.00h x 8.50w x 0.35d

ISBN13: 9781613253663

ISBN10: 1613253664

BISAC Categories:

- Transportation | Automotive | Repair & Maintenance